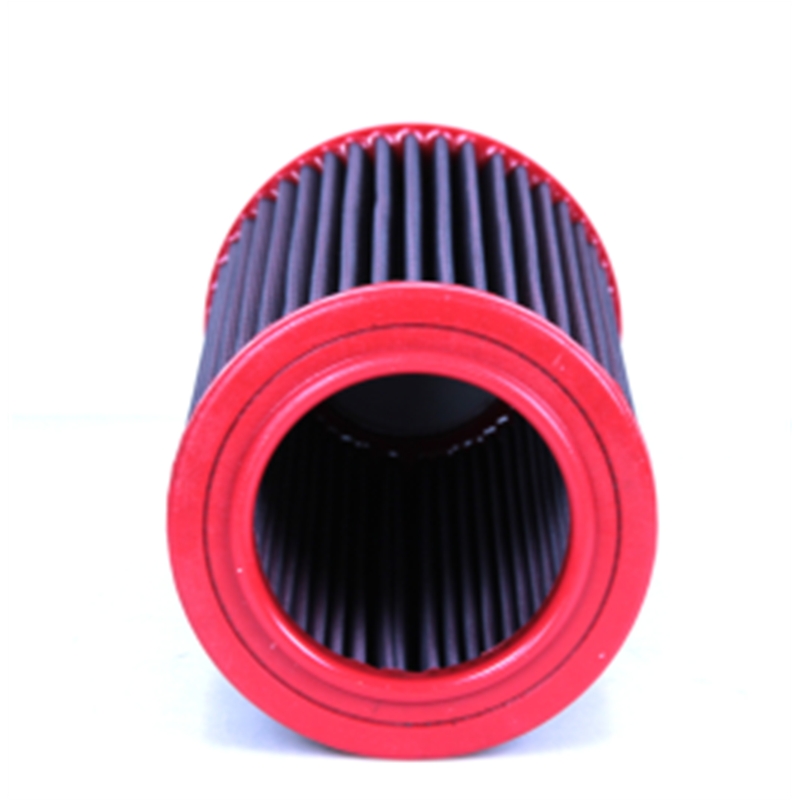

SPORT FILTER 12J 19J BMC

€79,30 VAT included

IN STOCK

Description

sizes (mm): D1 : 90 | D2 : 149 | H : 286

The cotton sports air filter is installed in the airbox to replace the original air filter. E’ produced with high-performance materials that allow an increase in the flow of air to the engine compared to the original paper or sponge air filter, while ensuring superior filtration efficiency: thanks to the combination of the different oiled layers, the containment of all impurities is guaranteed up to a minimum of 7 micron (ISO5011 international standard certificate for filtration), while OEM paper filters typically require total particle filtration down to a minimum of 10 micron.

Performance graph of the air flow on a sample BMC filter against a paper filter.

Temperature 25C ° – Humidity 25% – Pressure 1020mbar

The test is performed in the airbox, therefore with flow restrictions depending on the standard air inlet.

This chart non refers to the filter in question, but it is illustrative.

BMC cotton sports air filters are made using a process called “Full Moulding” which allows you to obtain the characteristic red filter from a single mold without requiring gluing in the corners, cause of easy breakage. The particular rubber used in BMC filtration systems is practically non-deformable over time and has excellent adhesion characteristics to any form of airbox..

BMC air filters are made of a multi-layer cotton fabric soaked in low viscosity oil, inserted between two aluminum reticulated structures. The aluminum nets are treated with epoxy resin in order to protect them from oxidation caused by fuel vapors and humidity in the air.

All BMC air filters are washable and regenerable using the special washing kit, allowing to save on the periodic replacement of the filter.

Related

Additional information

| Weight | 3,000 kg |

|---|---|

| Mark | |

| Template | |

| Category |

Reviews

There are no reviews yet.