DEFENDER BRAKE SERVO UPGRADE WITHOUT ABS FROM 1992 (YES HA701010) -L.O.F./TRW

Compatibility:

- Defender 90 200TDI – 300TDI – TD5 – TD4/PUMA (YES HA701010) NO ABS

- Defender 110 200TDI – 300TDI – TD5 – TD4/PUMA (YES HA701010) NO ABS

- Defender 130 200TDI – 300TDI – TD5 – TD4/PUMA (YES HA701010) NO ABS

€419,99 VAT included

IN STOCK

Description

This kit is for you!! Double your braking performance!

This kit will improve the performance of your Defender braking system whether you have standard brakes, Performance o Big!

Kit servo LOF POWERboost per Defender non ABS

Control list- This adapts to your Defender?

- Your Defender does not have the ABS

- Your Defender has 3 pipes from the main cylinder

- Your Defender is equipped with a master pumpBRAKE PUMP REVISION KIT

- Your Defender was made after the 1992

- Your Defender is a 200/300tdi/V8/TD5 / 2.4/2.2 TDCI

So what is it?

This kit allows you to remove the original brake servo, Remove the Lof PowerBoost Ring on the brake pedal and then install a next serving model SJG100240. Using this lof adapter, You can then reassemble your main cylinder of the original brake to the next, more powerful, double diaphragm servant, leaving your tank/cylinder in the correct position/orientation. In this way the service given to the main cylinder is doubled, reducing the effort of the pedal and significantly improving braking performance! So much so that the tests have shown that the braking is significantly better than an ABS Defender!

Assembly instructions:

- With the Lof PowerBoost and the new servant in hand, The assembly should not require more than 1 Now on 300TDI/ TD5 vehicles (TDCI may take longer)

- 300TDI and TD5 vehicles can have the lof powerboost installed without disconnecting the brake lines, which means that it is not necessary to perform the spurous of the brakes after installation

- Il 2.4/2.2 Tdci will need two new brake lines (1x 500mm and 1x 600mm male with male tubes) Because of this, You will also have to spread the brakes after assembly, Maybe take the opportunity to refresh the brake liquid?

- Open the hood and identify the position of the Master/Servant of the brake

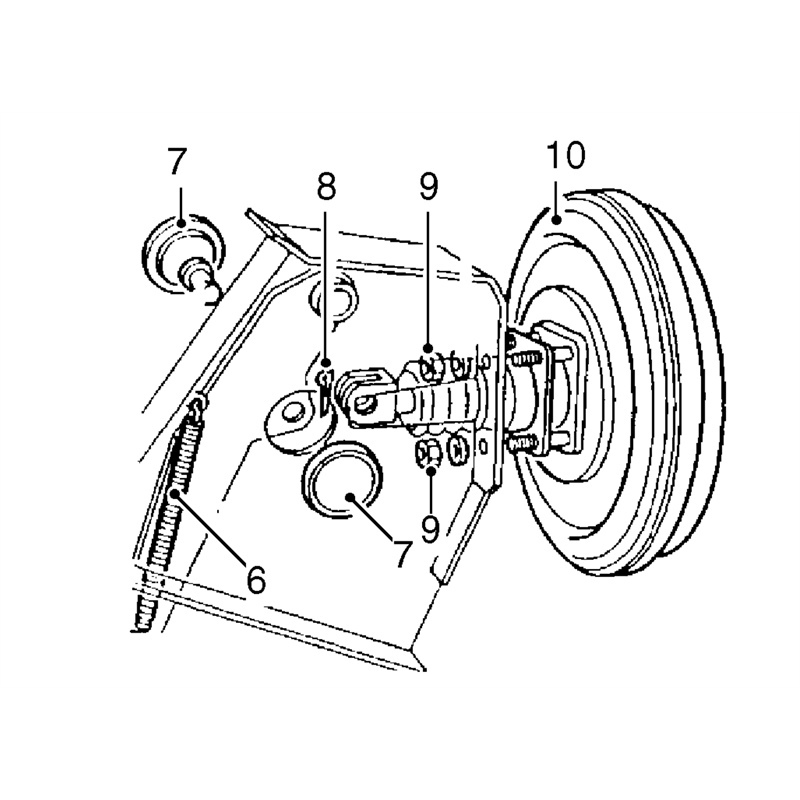

- Remove the 2 rubber eyelets on the side of the pedal box as shown in the diagram (Photo),

- Remove the divided pivot, The washer and pin of the Steca that connect the old brake serving to the pedal

- Disconnect the emptiness tube from the old servcum- this simply detaches

- Disconnect the clips of the brake tube that keep the brake pipes together, giving more flexibility for the movement (Do not disconnect the pipes!)

- Cancel 2x fixing nuts (testa 13 mm, M8) who keep the brake master's degree to the old serving

- Remove the main cylinder and move it to the side, paying attention not to damage or strive the pipes

- Cancel the 4X 13mm dice (M8) who keep the old serving at the pedal and remove the old servant

At this point he returns to the assembly, Take this moment to clean the pedal box/ any other easily accessible area

- Take the new servant and the Lof PowerBoost ring, Place the ring above the rear pins on the new double diaphragm servant, note that there are 2 Set of stunting holes, For this application it is necessary to use those further forward, clockwise.

- Use i 2 NYLOC FLIGNATI M8 supplied to tighten the ring to the new serving, up to a couple of 25 nm

- Take the entire group and install it again in the brake pedal box, Add the two dice freely on the back to keep it in place

- Asking an assistant to help, Move the brake pedal until the served holes align with the hole in the brake pedal arm and add the sealing pivot, staring with the washer + the split pin. 2x access gominas that can be adapted

- Double control- Now you should have the studs that aim outside the front of the servant, in position of the 10 and of 4 looking from the front!

- Tighten the 2x M8 dice that keep the new servant to the pedal box, to a couple of 25 nm

- Take the new rubber washer supplied in our kit and adapt it to the end of your original brake master, removing the old ring “O” present.

- TD5 and 300TDI owners: Now you can stay your brake Master up to the new pins servants, Noting that you will have to manipulate your 3x brake lines to reach, ensuring close curves or contact with other components that could rub / wear.

- TDCI owners: Now it may be necessary to disconnect 2 brake lines to allow the main cylinder to reach the required position, It will therefore be necessary to redo the 2 New lines (500 mm e 600 mm) To reach the Biess valve block. Then mount the main cylinder and reassemble the 2 New M8 dice. TDCI owners will now have to purge the brakes again to remove the air trapped in the system

- Tighten the M8 nuts of assembly of the main cylinder 2x a 25 nm

- Reconnect the emptiness tube to the new ABS servant

Once finished, Since you worked on the braking system, pump the pedal 4 times before starting the test drive!

This is a modification of the performance that we have tested in collaboration with independent specialists all over the world, However, it is your responsibility to make sure the kit is mounted correctly and safely, The retailer is not responsible for incorrect assembly!

Related

Additional information

| Weight | 11,000 kg |

|---|---|

| Mark | |

| Template | |

| Category |

Reviews

There are no reviews yet.